Introduction

In terms of producing long-lasting and attractive hardcover books, there is a material that always comes out on top: Book Binding Board. Also referred to as chip board, this product is a mainstay in the bookbinding sector. Its resilience, green credentials, and versatility contribute to its popularity among publishers, craftspeople, and manufacturers.

In this article, we’ll get into why Book Binding Board is the go-to choice for hardcovers and how it stacks up against its other counterparts. We’ll discuss its uses, advantages, and most important factors to consider that can guide you towards making well-informed decisions for your binding requirements.

What is Book Binding Board?

Defining Book Binding Board

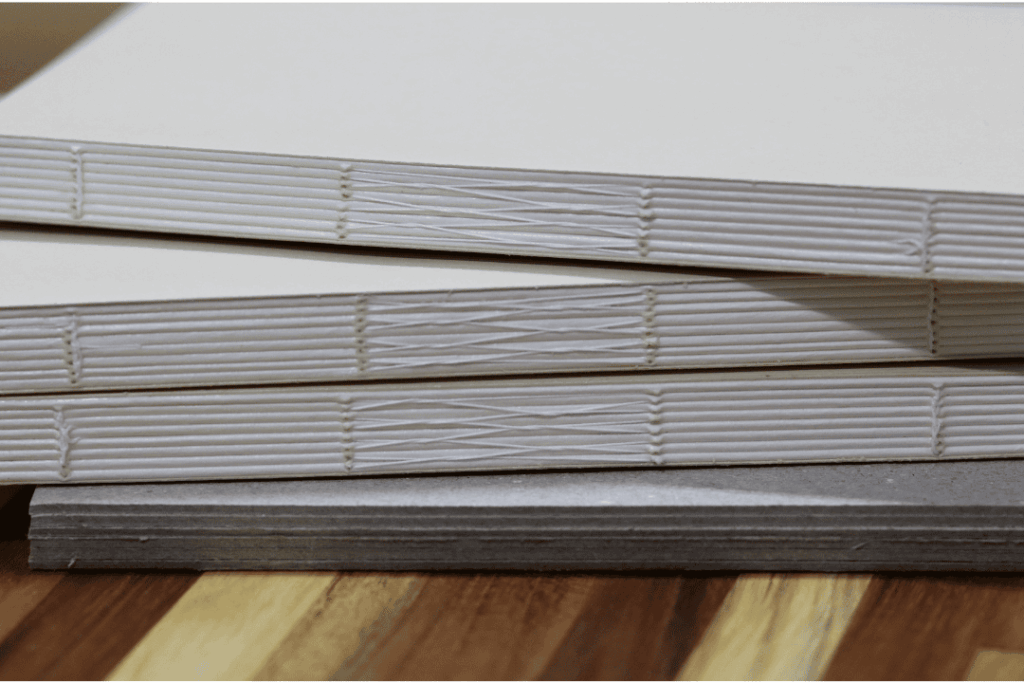

Book Binding Board, or chip board, is a dense, rigid paperboard produced by compressing thin layers of recycled paper. It is often employed in hardcover book production, notebooks, diaries, and other stationery products that need a firm backing.

This board provides a smooth surface that can be used for printing, wrapping, and pasting, and can easily be customized using fabrics, papers, or leather finishes. It comes in different thicknesses, usually between 1mm and 4mm, depending on the strength and flexibility required.

Why Use Book Binding Board for Hardcovers?

Durability and Strength

One of the primary reasons publishers opt for back, stitchery Board is its exceptional durability. This material resists bending, folding, and warping, ensuring that books retain their structure over time, even with frequent use.

Aesthetic Appeal

Besides its strength, back, stitchery adds a polished, professional look to hardcovers. It offers a consistent shape and smooth texture that complements high-quality book covers.

Customization Options

From leather to cloth and printed paper, back, stitchery can accommodate a wide range of cover materials. This makes it highly versatile for publishers and bookbinding artisans.

Cost-Effective Material

Compared to other hardcover materials like plastic or metal, back, stitchery is affordable and readily available. Its cost-effectiveness makes it ideal for mass production without compromising quality.

Applications of Book Binding Board

Common Uses in Bookbinding

Hardcover Books

The most common application of Book Binding Board is in manufacturing hardcover books. It provides the firm foundation needed to protect the pages and support the spine.

Custom Notebooks and Diaries

Whether you’re creating personalized journals or premium business diaries, back, stitchery Board offers a premium look and feel that enhances value.

Educational and Institutional Books

Due to its durability and ease of customization, educational institutions often use back, stitchery Board for textbooks and reference materials.

Portfolio and Presentation Books

Artists, architects, and designers often use back, stitchery to create portfolios or presentation books that require both style and structure.

Comparing Book Binding Board with Other Materials

Book Binding Board vs. Plastic Covers

Plastic covers might be waterproof and lightweight, but they lack the classic and premium look that back, stitchery provides. Additionally, plastic is not biodegradable, while chip board is often made from recycled materialsrecycled materialsrecycled materials.

Book Binding Board vs. Leather Covers

Leather provides a luxurious finish but at a higher cost and with limited eco-friendly options. back, stitchery offers a comparable look when wrapped in synthetic materials or leatherette, making it a practical alternative.

Environmental Benefits of Book Binding Board

Sustainability

A major advantage of back, stitchery is that it is often made from recycled paper. This reduces environmental impact and supports sustainable manufacturing practices.

Low Waste Production

The manufacturing process of back, stitchery produces minimal waste and often recycles its own scraps back into production.

Biodegradable

Unlike plastic alternatives back, stitchery is biodegradable, which makes it a more eco-friendly choice for environmentally conscious brands.

Factors to Consider When Choosing Book Binding Board

Thickness and Weight

The thickness of back, stitchery affects the final product’s sturdiness and weight. For larger books, thicker boards provide more stability.

Surface Finish

A smooth surface ensures better adhesion when wrapping the board with paper or fabric. Some boards also come with pre-coated finishes.

Sourcing and Cost

Reliable suppliers offer consistent quality. When sourcing materials, it’s crucial to balance cost with board quality, especially in bulk purchases.

FAQs:

Q1: What is the ideal thickness for a Book Binding Board?

A: For standard hardcover books, a thickness of 2.5mm to 3mm works best. However, thicker boards are used for oversized books.

Q2: Can Book Binding Board be printed on directly?

A: While it can be printed, most publishers wrap it with printed paper or fabric for better results.

Q3: Is Book Binding Board eco-friendly?

A: Yes, especially when made from recycled paper. It’s a sustainable option compared to plastic or synthetic boards.

Q4: Can Book Binding Board be used with other sustainable materials like Recycled Board?

A: Absolutely. Many manufacturers combine back, stitchery Board with Recycled Board for added environmental benefits.

Conclusion

back, stitchery is a critical material in hardcover book manufacturing. Its durability, affordability, and versatility make it the first line of choice for manufacturers and designers. It finds use in customized notebooks to academic journals, its applications are immense and precious.

In a world where sustainability is gaining greater significance, combining environmentally friendly solutions such as back, stitchery Board and Recycled Board provides a quality and responsible solution to the needs of publishing today.

Whether you’re a commercial press, craft binder, or self-publisher, making an investment in quality back, stitchery Board can improve your work and provide long-lasting outcomes