Our Products

PLA Coated Glassine Paper

PLA Coated Glassine Paper is a sustainable and versatile packaging material that combines the smooth, translucent properties of traditional glassine paper with an eco-friendly PLA (Polylactic Acid) coating. The PLA layer, derived from renewable plant sources, provides excellent moisture and grease resistance—making it ideal for wrapping food, baked goods, cosmetics, and delicate items. Unlike petroleum-based coatings, PLA is biodegradable and compostable under industrial conditions, helping brands reduce plastic waste. Lightweight, recyclable, and protective, PLA Coated Glassine Paper is a smart choice for businesses looking to balance performance with sustainability.

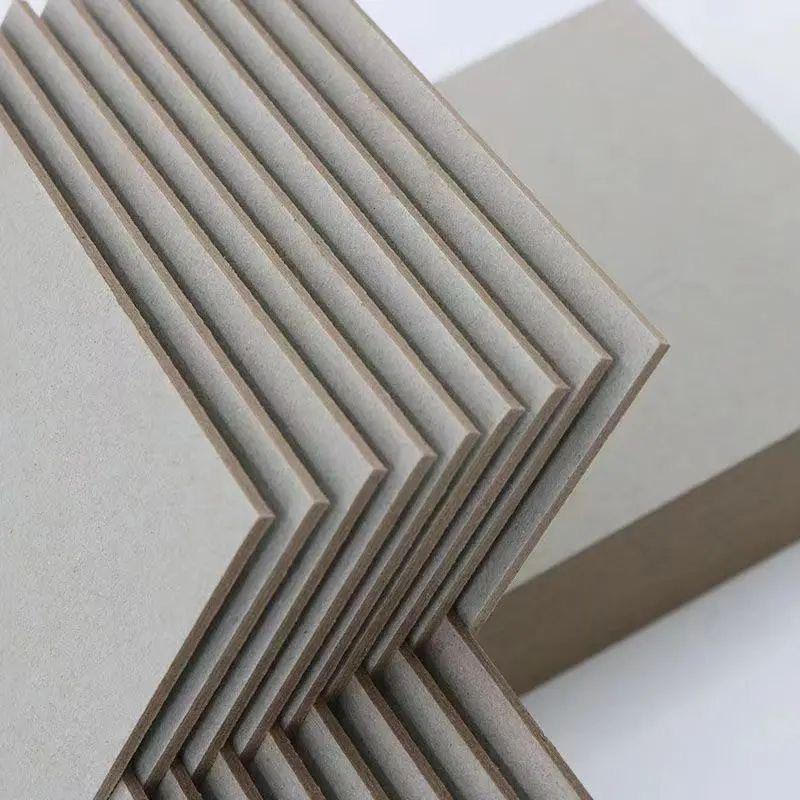

High-Quality Kappa Board Products for Various Applications

Our company is proud to offer a diverse range of premium Kappa Board products designed for various applications. Our product lineup includes vibrant colored boards, durable rigid box boards, and PE-coated paper boards. Each of these products is crafted using the finest materials and advanced manufacturing techniques, ensuring exceptional strength, durability, and reliability. With a commitment to quality, we deliver solutions that meet the highest industry standards, providing our customers with dependable and versatile boards for all their needs.

Kappa Board-Description

Our Kappa Board is a top-tier, laminated solid board made entirely from 100% recycled paper, designed to provide unmatched flatness and stability. Once processed, Kappa Board is guaranteed to stay flat, ensuring that it performs consistently throughout its entire lifecycle. This is achieved through our proprietary production methods, including the use of specially designed lining paper and meticulous control of the production process, along with maintaining the perfect humidity conditions. With Kappa Board, you can trust in its reliable flatness at all stages.

- High rigidity

- Lays flat and stays flat

- Even surface

- Optimal run ability

- Easy to cut, die cut, crease, score, gouge, mill, punch, drill and emboss/deboss

| THICKNESS | 1 MM TO 4 MM |

|---|---|

| GSM | 660 GSM TO 2640 GSM |