Introduction

When you pick up a hardbound book or a sophisticated gift box, you might be drawn to the cover, the print, or the shine of the foil stamping. But what really gives that box or book its strength is the paper board inside. The texture and look of these products are subtly but significantly influenced by the quality of the paper board manufacturer. Without strong and smooth paper boards, packaging would feel weak, and covers would bend or lose shape.

why choose the paper board

The types of paper boards that are used, the significance of selecting the correct manufacturer, and their application in packaging solutions for different industries will all be covered in this article.

Why a Paper Board Manufacturer Matters

Foundation of Packaging

No matter how creative the design, packaging cannot stand strong without the right board. The job of a Paper Board Manufacturer is to make boards that give structure, protect products, and at the same time look professional when wrapped in paper, cloth, or foil.

Quality Reflects on the Brand

If you are selling luxury goods, a weak package can ruin the customer’s first impression. Robust boards guarantee that the box won’t bend, the lid will fit precisely, and the finished product will feel high-end. That is why big brands trust experienced manufacturers.

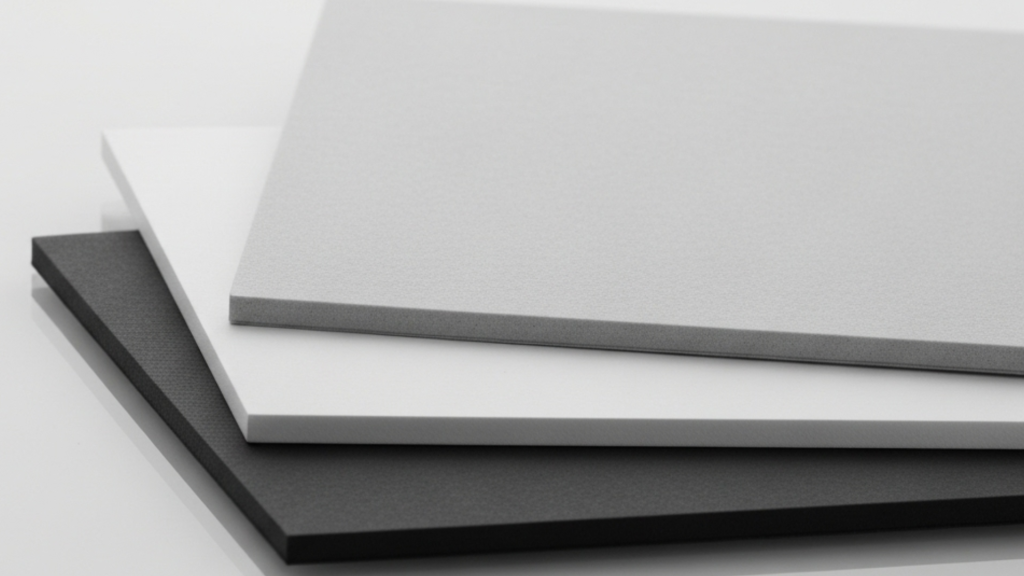

Types of Paper Boards You Should Know

Duplex Board

One of the most common options is Duplex Board, usually made with two layers that provide strength and a smooth surface. It is eco-friendly, cost-effective, and gives strong support. Duplex boards are widely used in bookbinding, stationery, and packaging boxes.

Kappa Board

Another option from many Paper Board Manufacturer companies is the Kappa Board. It is lighter but still has high strength. Many businesses choose it for packaging where weight matters, such as shipping or children’s books.

Features of Premium Paper Boards

Durability and Strength

Good paper boards do not warp when exposed to heat, glue, or pressure during the production process. They stay flat, which is important for clean packaging.

Smooth Surface

A premium board has a smooth finish. This matters because cloth, leather, or foil covers stick better on an even surface. Smooth boards also give neat edges when cut.

Simple to Cut and Form

Boards are made by manufacturers to be easily cut to any size. This decreases waste and speeds up the production process.

Tailored Packaging Options

Exquisite Packaging

Brands that sell watches, jewelry, or cosmetics frequently require boxes that have a luxurious feel. Premium boards make sure these boxes look stylish while keeping the product safe.

Food and Beverage

Packaging for cakes, wine bottles, or chocolates needs strong boards that can handle weight and keep shape. A trusted Paper Board Manufacturer provides boards suitable for food-safe packaging.

Books and Stationery

Smooth boards give covers for hardcover books and diaries a polished appearance and longer shelf life.

Paper Board Sustainability

Nowadays, a lot of businesses favor environmentally friendly solutions. Many boards are frequently composed of recycled materials, which appeals to companies that support sustainability. There are now eco-certified versions available as well. Asking a supplier about recycling and sourcing is important if your project demands eco standards.

How to Select the Right Paper Board Manufacturer

Consistency in Quality

You do not want one batch of boards strong and another batch weak. A reliable Paper Board Manufacturer ensures every delivery has the same quality.

Good Storage

Boards can absorb moisture if not stored properly. Manufacturers who care about storage and handling will provide boards that stay flat and strong.

Knowledgeable Support

Sometimes you may not be sure which type of board you actually need. A good supplier will help you make the best decision by outlining the differences.

Typical Errors People Make

- choosing a thin, easily bending board for heavy packaging.

- failing to verify that the board’s surface is sufficiently smooth for foil stamping.

- disregarding environmentally friendly options despite the brand’s advocacy for sustainability.

Why Premium Boards Improve Packaging Value

When a customer holds a strong, neatly finished box, it builds trust in the brand. High-quality boards give a sense of luxury and weight. Additionally, they prolong the shelf life of packaging, which is important for goods that are used frequently or kept on shelves. Although a cheap box might initially save money, it can eventually harm a brand’s reputation

Paper Boards’ Future in Packaging

Packaging that is sustainable and intelligent is becoming more and more in demand. A large number of paper board manufacturers are making investments in digitally printed boards, lighter boards with comparable strength, and recycled materials. Even more sophisticated solutions appear to be in store for the future.

FAQs Regarding Paper Board Manufacturer

1. What distinguishes one type of board from Grey Board?

While this option is stronger but lighter, Grey Board is heavier and primarily composed of recycled paper. Depending on the requirements of the project, both are frequently utilized.

2. Can paper boards be used for food packaging?

Yes, when coated with food-safe materials, a variety of boards can be used for food packaging. Consult the paper board manufacturer at all times.

3. Does packaging require a smooth finish?

Indeed, a smooth finish improves the adhesion of wrapping or covers, particularly for cloth or foil stamping.

4. Are all paper boards eco-friendly?

Not all. While most options are environmentally friendly, you should check to see if the manufacturer of Kappa board uses sustainable or recycled materials.

Conclusion

A manufacturer of paper board is more than just a supplier of sheets. They collaborate to develop robust, fashionable, and environmentally friendly packaging solutions. The right choice of material defines how the final product looks and feels.

When you select a manufacturer, always check their consistency, knowledge, and ability to deliver boards that meet your needs. Premium paper boards do not only make packaging stronger, they also build brand value and customer trust. Whether for books, luxury boxes, or food products, the right board is the backbone of quality packaging.